23 mai 2012

3

23

/05

/mai

/2012

04:18

繼上一篇介紹去除材料方式的面加工後,本篇介紹無切削方式的鏡面加工。

無切削方式

常見加工為滾壓加工,是一種無切屑加工,在常溫下利用金屬的塑性變形,使工件表面的微觀不平度輾平從而達到改變表層結構、機械特性、形狀和尺寸的目的。因此這種方法可同時達到光整加工及強化兩種目的,是磨削、車削等機械加工無法做到且無切削加工技術安全、方便,能精確控制精度,滾壓後的表層金屬纖維完整。

在滾壓加工中常使用刀具為擠光刀,利用擠光刀機械擠壓的原理,獲得光潔如鏡的金屬表面的一種機械加工方法。擠壓刀加工是一種無切屑加工,在常溫下利用金屬的塑性變形,使工件表面的微觀不

平度輾平從而達到改變表層結構、機械特性、形狀和尺寸的目的。因此這種方法可同時達到光整加工及強化兩種目的,是磨削無法做到的。

滾壓加工原理:它是一種壓力光整加工,是利用金屬在常溫狀態的冷塑性特點,利用滾壓工具對工件表面施加一定的壓力,使工件表層金屬產生塑性流動,填入到原始殘留的低 凹波谷中,而達到工件表面粗糙值降低。由於被滾壓的表層金屬塑性變形,使表層組織冷硬化和晶粒變細,形成緻密的纖維狀,並形成殘餘應力層,硬度和強度提 高,從而改善了工件表面的耐磨性、耐蝕性和配合性。滾壓是一種無切削的塑性加工方法。

參考資料來源:百度百科

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。

機械類則有對刀具加工非常有幫助的冷風槍、渦流管槍,並有最新設計和技術的粉末成型機。

碧威是在刀具製造及機械工具業界中具有足夠水準的製造供應商!

willy

16 mai 2012

3

16

/05

/mai

/2012

02:58

In recent years, machining center spindle is more and more speedy. For fitting the requirement of high speed machining on high hardness and strength materials and also prolonging mold life, the

cutting tools advance its technology accordingly.

According to the processing demand, we will select the appropriate tool in accordance with the following recommendations:

-

Basic cutting material of work piece, material properties, conditions, and manufacture processes….

For example: customers’ demand about size, tolerance range, result up to mirror face, corner without joint point of tool exchange, cutting path of NC program, applications, and related

issues.

-

To clarify different material of cutting tools (like difference of hardness and strength…)

Approx. types of cutters: single crystal diamond cutting tools, PCDs contenting CO diamond cutting tools, PCD

containing Si diamond tools, PCBN cutting tools, metal porcelain cutters, tungsten carbide tools,

HSS cutting tools, general steel cutters. Select proper cutting tools according to work piece.

-

According to the special requirements of the work piece shape (for example: deep groove surface of work piece ...)

Generally based around the shape, surface tensile, surface rotation, ball rounded shape, conic, cylindrical curve shape, and other relevant conditions of work piece to choose the shape of end

mills. The neck types of end mills are divided into standard, long-neck, and cone-neck. Select cutters according to the machining depth of the work piece, shape, appearance, processing

objects, crude/middle/fine three milling paths, and other related conditions. Long-neck and cone-neck types can process deep machining, it should take into account about the interference

angle during selection in both .., Compared with the long-neck type, the high rigidity of the cone neck type milling cutter may promote cutting conditions and achieve better machining

accuracy, you should choose cone-neck type end mills.

-

According to the machining accuracy and delicate face of work piece to select different ball head accuracy and smooth edge end mills.

The arc accuracy of ball end mills is typically ± 5μm; there are also ± 2 ~ 3μm high-precision end mills available for high-precision

processing.

-

According to the kinds and the hardness of the work piece to select the coating types of tools.

BW TiALN coating is suitable for machining carbon steel and hardness below HRC40 of work piece; Nano titanium aluminum nitride film-NanoTiAlN coating is for alloy steel S, tool steel, and

HRC50 work piece; BW TiALN + PLCcoating. Is good for higher hardness, hard alloy material of work piece.

-

If the work pieces are hard-to-cut, and special material, you should choose high hardness cutters like metal ceramic and diamond tool.

For example: if cutting metal composite material, you should choose BW metal ceramic cutter or

PCBN diamond tool to solve cutting problems because the material is with high nickel content.

Bewise Inc., being a professional manufacturer of various cutting tools, is endeavoring to make

excellent products. We are very experienced in custom-made tools, and good at solving customers’ problems when they meet difficulties and troubles. Through everlasting research and practices, we

understand thoroughly about different materials of cutters and cutting tools.

BW's popular products for tool series including circular saw, carbide cutting tool,

saw blade, wood saw blade, special tool,side milling cutter, …etc; For machines we have spiral tube cooler, cutter grinder, and the latest design and advanced powder forming machine / pelletizer. Bewise is a superior manufacturer and supplier of cutter

production and machinery industry.

willy

16 mai 2012

3

16

/05

/mai

/2012

02:52

BW supply and organize full production lines according to demand of Common Mode inductor producing. Common Mode Inductor whole production line: automatic winding two-lane special equipment,

inductor-based visual positioning assembly machine, inductive type high-speed assembly machine, and automatic packaging machine. Common mode Choke, also known as common mode chokes for switching

power supply, which is an important part of inverter, UPS power supplies and other equipment.

|

|

|

|

Common Mode

Winding Machine

|

Common Mode

Inductor Auto Mount Machine For 2012

|

Common Mode

Inductor Auto Mount Machine For 1608

|

Common Mode

Taping Machine

|

1.Stand alone tool

2.Operation rate:95%

3.Chips size :2012

4.Throughput :8s/pcs

|

1.Stand alone tool

2.Operation rate : 99.8%

3.Chips size : 2012

4.Throughput : 2 sec. / 2 pcs

|

1.Type: Stand alone tool

2.Operation rate:99%

3.Chips size : 1608

4.Throughput : <2 sec. / 1pcs

|

1.Stand alone tool

2.operation rate :99%

3.chips size :3216~1210

4.throughput :2 pcs / sec.

|

Bewise Inc., being a professional manufacturer of various cutting tools, is endeavoring to make

excellent products. We are very experienced in custom-made tools, and good at solving customers’ problems when they meet difficulties and troubles. Through everlasting research and practices, we

understand thoroughly about different materials of cutters and cutting tools.

BW's popular products for tool series including circular saw, carbide cutting tool,

saw blade, wood saw blade, special tool,side milling cutter, …etc; For machines we have spiral tube cooler, cutter grinder, and the latest design and advanced powder forming machine / pelletizer. Bewise is a superior manufacturer and supplier of cutter

production and machinery industry.

willy

16 mai 2012

3

16

/05

/mai

/2012

02:46

無論用何種金屬加工方法加工,在零件表面總會留下微細的凸凹不平的刀痕,出現交錯起伏的峰穀現象,粗加工後的表面用肉眼就能看到,精加工後的表面用放大鏡 或顯微鏡仍能觀察到。這就是零件加工後的表面粗糙度,過去稱為表面光潔度。鏡面加工一般是工件表面粗糙度<0.8um的表面時,稱為鏡面加工。

常見鏡面的機械加工方法有:

- 去除材料方式:磨削、研磨、拋光、電火花。

- 無切削方式(滾壓加工):滾壓(採用鏡面工具)、擠壓。

※去除材料方式

常見加工為鏡面切削,是採用運動精度及剛性高之工作母機及擁有平滑輪廓的鑽石刀具,依據母性原理從事切削加工,然後將金屬、各種結晶材料、塑膠等表面加工程鏡面的技術。利用本技術加工而成之鏡面和以往利用磨粒加工之鏡面比較時,不僅能獲得較高的形狀精度,還具有在大波長範圍內對於反射率或雷射光的耐熱損傷性也很高,同時加工成本低等特色。

由於金剛石易與鐵族金屬發生化學反應,因此不適合加工淬硬鋼等工件材料,僅局限於加工非電解鍍鎳等非鐵金屬。但近年來,由於採用超聲波橢圓振動切削的加工機床性能的改進,單晶鑽石刀具也能用於淬硬鋼等鐵族金屬的鏡面加工。 鑽石是硬度最高、導熱性能最佳的刀具材料,在難加工材料的切削加工、幹式和半幹式切削加工中刀具有很長的使用壽命且鑽石刀具能獲得非常鋒利而無凹凸鋸齒的切削刃。因聚晶金剛石粒子間的結合強度弱于單晶金剛石,因此刃磨後的切削刃也會產生晶介面的凹凸和粒子脫落現象,故常使用刀具為單晶鑽石刀具。單晶鑽石切削刀具主要用於非球面透鏡、衍射光柵高精度光學元件的加工。

參考資料來源:百度百科

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。

機械類則有對刀具加工非常有幫助的冷風槍、渦流管槍,並有最新設計和技術的粉末成型機。

碧威是在刀具製造及機械工具業界中具有足夠水準的製造供應商!

willy

9 mai 2012

3

09

/05

/mai

/2012

07:36

Step drill, the related accuracy in manufacture process is the most important factor for cutting quality. If the precision isn’t controlled well, it will cause hole too rough and even caused

reject of work piece. Not only geometry, specification, accuracy, and surface quality, but also the drill volume are important points for the cutting quality of step drill.

During drill process, if the chip groove isn’t well-produced, it would happen wall friction, extrusion, brushed and scratches on its surface. It will cause the bad quality of working surface and

obstruction, drill bit stuck, and even broken the drill bit.

|

BW-90° Step Drill

|

General-90° Step Drill

|

|

|

General step drill doesn’t grind a ramp edge in the step part, BW designs a ramp in the step part of drill to make chip removal easier, and also reduce the friction heat caused by the accumulated

chips. The first and the second steps are vertical, so it is difficult to cut a gap in these parts during manufacture.

Bewise Inc., being a professional manufacturer of various cutting tools, is endeavoring to make

excellent products. We are very experienced in custom-made tools, and good at solving customers’ problems when they meet difficulties and troubles. Through everlasting research and practices, we

understand thoroughly about different materials of cutters and cutting tools.

BW's popular products for tool series including circular saw, carbide cutting tool,

saw blade, wood saw blade, special tool,side milling cutter, …etc; For machines we have spiral tube cooler, cutter grinder, and the latest design and advanced powder forming machine / pelletizer. Bewise is a superior manufacturer and supplier of cutter

production and machinery industry.

willy

9 mai 2012

3

09

/05

/mai

/2012

05:24

BW’s advanced metal-ceramic brazed circular saw has better flexural strength in machining high hardness alloy which content 18% up of Ni and more superior

damage resistance and stable quality in wet machining than HSS saw.

Characteristics of metal ceramic:

- Stable cutting efficiency in wet machining.

- Better than the nano-tungsten carbide material for damage and abrasion resistances.

Characteristics of metal ceramic blade:

- The cutting edge is with self-sharpening effect of re-grinding.

- Stable chemical results.

- No infiltration effects on the blades.

- There is no pollution by using Co as the metal bonding material, instead of the mixture of Ni and Co.

- More safe during processing.

- Wider applications.

- Increasing the surface finish and accuracy.

- Enhancing the continuous processing capacity.

Material composition:

|

component

|

Color

|

Specific Gravity.

|

Hardness

(HV)

|

Hardness

(Gpa)

|

Fracture Toughness

(Mpa.m1/2)

|

Flexural strength

(Mpa)

|

|

TiCN+Nb

|

bluish-gray

|

6.4

|

1500~1650

|

14.5~16.2

|

10.0~10.5

|

2500~1960

|

Bewise Inc., being a professional manufacturer of various cutting tools, is endeavoring to make

excellent products. We are very experienced in custom-made tools, and good at solving customers’ problems when they meet difficulties and troubles. Through everlasting research and practices, we

understand thoroughly about different materials of cutters and cutting tools.

BW's popular products for tool series including circular saw, carbide cutting tool,

saw blade, wood saw blade, special tool,side milling cutter, …etc; For machines we have spiral tube cooler, cutter grinder, and the latest design and advanced powder forming machine / pelletizer. Bewise is a superior manufacturer and supplier of cutter

production and machinery industry.

willy

9 mai 2012

3

09

/05

/mai

/2012

05:17

暨上一篇的銑床精度介紹,現在來看看機台校正步驟的細節囉!

機台校正步驟如下(點下方項目連到該步驟)

-

銑床水平精度檢驗與校正

-

工作台移動平行度檢驗

-

主軸、主軸端面振幅檢驗

-

銑床進給刻度環校正

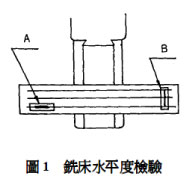

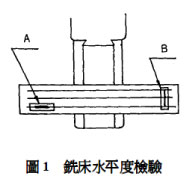

一、銑床水平精度檢驗與校正

- 將銑床工作台面以及兩個水平儀底座擦拭乾淨。

- 如圖1所示,將兩個水平儀安裝在工作台上。

- 檢查並記錄水平儀上刻度值。

- 若水平儀刻度值小於0.06 ㎜/m 之值則銑床水平精度合乎標準,無需水校正。

- 若水平儀刻度值大於0.06 ㎜/m 之值,則依步驟6 至步驟8 進行水平正。

- 放鬆銑床台座固定螺栓,於台座底下墊入鐵片調整銑床水平度,直至工作台上縱向與橫向之水平度均在0.06㎜/m之內。

- 鎖緊底座固定螺栓。

- 重新將正確的水平值記錄於檢驗卡上。

※0.06㎜/m:是水平度、垂直度或平行度的數值,表示在1公尺的長度內,容許有0.06㎜以內的測定誤差量。

二、工作台移動平行度檢驗

操作步驟:

- 如圖2所示,將量錶固定在心軸,觸針輕微接觸在工作台面上。

- 移動工作台,作縱向及橫向移動,同時檢查量表指針移動量,其值即為工作台移動平行精度。

- 記錄工作台移動平行精度於銑床定期保養記錄卡。

- 銑床縱向移動精度是0.02㎜/500㎜,橫向移動精度是0.02㎜/300㎜,銑床經檢驗後若其精度值於上述容許範圍內,則其移動平行精度合乎規定,無需校正。

- 若銑床經檢驗後,其精度值超過容許誤差值時,則以銑床維護保養單元的方法,調整床台進給機構上楔片的配合至適當緊度,使床台的移動可以圓滑平順,再重覆步驟2至4的檢驗工作。

- 若銑床經楔片調整後再檢驗其平行精度值仍超過容許誤差值時,請通知製造廠商校正服務。

三、主軸、主軸端面振幅檢驗

- 如上圖所示,將量錶固定於工作台上,觸針輕微接觸在主軸外徑及主軸端面。

- 調整銑床變速桿至空檔位置。

- 用手轉動主軸,同時讀出量錶指針的移動量,此值即為銑床主軸偏擺量。

- 記錄銑床主軸偏擺量於定期保養記錄卡上。

- 銑床主軸偏擺容許誤差是0.01 ㎜,若銑床主軸偏擺量小於0.01 ㎜,則其偏擺量正常,無需校正。

- 若銑床主軸偏擺量大於0.01㎜,則調整主軸上方定位螺帽至適當緊度,再重覆上述步驟,重新檢驗其偏擺度。

- 若經多次調整主軸定位螺帽後,其偏擺度仍大於容許誤差值0.01㎜,則通知製造廠商校正服務。

四、銑床進給刻度環校正

操作步驟

- 用手輕輕轉動縱向、橫向進給手輪,感覺出手輪的空轉範圍,此空轉範圍即為導螺桿進給齒隙。

- 從刻度環讀出手輪空轉範圍的誤差值。

- 導桿進給齒隙最大容許值是0.127㎜。

- 若導桿齒隙超過0.127㎜時,需調整進給機構上螺桿背隙消除裝置,使空轉齒隙減少至許可範圍之內。

銑床之精度於銑床出廠時,已經過檢驗合格,銑床使用一段時間後,其精度有偏差的情形是因為機件變形或磨損引起的,必須給予校正,但銑床精度的校正工作,有時需使用專業的技術或特殊的儀器,例如工作台刮削或銑床主軸偏擺校正,都不是銑床操作工的技術領域,因此必需委由銑床製造廠商校正才能達到事半功倍的專業效果,為避免銑床精度產生偏差,銑床操作人員必須注意正常的操作與定時的保養,如果機器操作很正常,切削進給不過載,不撞機並且潤滑足夠,那銑床的精度可以確保很長的時間。

參考資料來源:職業訓練局-銑床精度校正

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。

機械類則有對刀具加工非常有幫助的冷風槍、渦流管槍,並有最新設計和技術的粉末成型機。

碧威是在刀具製造及機械工具業界中具有足夠水準的製造供應商!

willy

27 avril 2012

5

27

/04

/avril

/2012

05:14

本機規格

-

型式:油壓式<雙向加壓>

-

規格:150噸

-

電壓:220V/380V

-

操作介面:人機介面系統

-

本體機台:

-

主油壓缸:直徑320mm

-

側油壓缸:直徑125mm

-

送料缸:直徑30mm

-

模組:模浮動上一下一

-

油壓系統規格:

-

馬力:主馬力25HP

-

輔助馬力:2HP

-

油箱:800L

本機特點

- 利用油壓之穩定性及配合精密模具之結構,藉數控壓力表,使操作更加簡易,提升產 品之穩定性及良率。

- 在產品區隔上,可利用程式編碼做特殊動作,達到產品要求。

- 本機採用、提高電控操作便利性及故障原因說明、讓現場操作人員更有效率掌握進度 及機台之順利運轉。

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在 客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為 圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。

機械類則有對刀具加工非常有幫助的冷風槍、渦流管槍,並有最新設計和技術的粉末成型機。

碧威是在刀具製造及機械工具業界中具有足夠水準的製造供應商!

willy

27 avril 2012

5

27

/04

/avril

/2012

04:57

銑床在加工時,無論是刀具或是機器上的機件都會有複雜的交變應力,銑床於使用一段時間之後,或許因為機器 本身穩固性鬆動,或許因為機件磨損或變形而使其精密度產生偏差,舉例來說:刀桿夾持長度及偏擺太多,

原兩刃的刀其實只有1刃在切削,等於刀具使用的時效,只剩1/2而已;夾持精度越高代 表刀具在尾端擺動量越小,也因此使用者可輕易達到工件所要求之精度或面粗度;另外 ,主軸偏擺會產生離心力會導致刀具在加工時,機台會晃動外,只用到單邊進行銑削造成刀具會磨損的

嚴重或工件損壞,而轉速進給也會使刀具磨損。因此,機器經過一段時間的使用之後,就必須實施所謂 的定期保養,定期保養校正可以確保銑床的精度及加工的品質,有高品質的機器,才能加工出高品質的工件 。

-

銑床水平校正

銑床的水平度不足,銑床操作時容易產生震動,並且銑床的床 台也容易因受力不平均而產生變形。

-

銑床床台進給精度校正

床台即需不停的移動以達到切削進給的目的,因此, 銑床經過一段時間的使用之後,床台進給機構的配合面會有或多或少的磨損,使床台進給機構的配合面間產 生鬆動或是其水平度或垂直度產生偏差。因此,床台進給的平行度、垂直度等需定期的檢驗及調整,才能確 保銑床加工的精確度。

-

銑床主軸的偏轉度校正

銑床在實際加工時,或因為銑床主軸偏心,或因為銑 刀安裝偏差,銑刀轉動時,有 產生偏轉的現象,銑刀如果產生偏轉,則銑床將大大的降低了加工的效率,因此,銑刀

轉動時,其同心度是很重要的。銑床主軸正直度是影響銑刀偏轉的最重要因素,所以銑床需定期檢驗主軸旋 轉的同心度,如果發現機器之主軸有偏轉情形,必須給予校正,以確保機器的加工效能。

-

銑床床台進給刻度環校正

銑床加工的工件都有一定的尺寸標準,銑床加工控 制尺寸的方法是應用銑床進給刻度環,如果銑床進給刻度環有鬆脫或磨損時,將導致工件加工尺寸控制不準 確的結果。所以銑床進給刻度環必須經常調整,使床台進給機構之間隙能保持最小的誤差值,以確保銑床加 工尺寸有效的控制。

下一篇來為您介紹銑床精度與校 正-part2機台校正步驟

參考資料來源:職業訓練局-銑床精度校正

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在 客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為 圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。

機械類則有對刀具加工非常有幫助的冷風槍、渦流管槍,並有最新設計和技術的粉末成型機。

碧威是在刀具製造及機械工具業界中具有足夠水準的製造供應商!

willy

27 avril 2012

5

27

/04

/avril

/2012

03:45

Features of graphite crucible:

- High temperature resistance and special thermal properties

- Excellent electrical conductivity and thermal conductivity

- Lubricity

- Covering and plasticity

- Chemical stability

Application:

Graphite used mainly on of metallurgy, specialized in producing fire-resistant materials, such as graphite crucible, blast furnace lining, heat preservation medicinal preparation and carbon

agent. The melting point of graphite is higher, gasification till 4500 ° C. Its performance of fire-resistant and anti-corrosion may be significantly improved after adding carbon formed from

graphite.

Bewise Inc., being a professional manufacturer of various cutting tools, is endeavoring to make

excellent products. We are very experienced in custom-made tools, and good at solving customers’ problems when they meet difficulties and troubles. Through everlasting research and practices, we

understand thoroughly about different materials of cutters and cutting tools.

BW's popular products for tool series including circular saw, carbide cutting tool,

saw blade, wood saw blade, special tool,side milling cutter, …etc; For machines we have spiral tube cooler, cutter grinder, and the latest design and advanced powder forming machine / pelletizer. Bewise is a superior manufacturer and supplier of cutter

production and machinery industry.

willy