10 octobre 2012

3

10

/10

/octobre

/2012

05:08

不銹鋼通俗地說,不銹鋼就是不容易生銹的鋼,實際上一部分不銹鋼,既有不鏽性,又有耐酸性(耐蝕性)。不鏽鋼的不鏽性和耐蝕性是由於其表面上富鉻氧化膜(鈍化膜)的形成。由於不銹鋼材具有優異的耐蝕性、成型

性、相容性以及在很寬溫度範圍內的強韌性等系列特點,所以在重工業、輕工業、生活用品行業以及建築裝 飾等行業中獲取得廣泛的應用。上一篇”不鏽鋼介紹”有更詳細介紹,此篇介紹各種不銹鋼標準鋼號對照表。

不銹鋼標準鋼號對照表:

中國

GB1220-92[84]

GB3220-92[84]

|

日本

JIS

|

美國

AISI UNS

|

英國

BS 970 Part4

BS 1449 Part2

|

德國

DIN 17440

DIN 17224

|

|

1Cr17Mn6Ni5N

|

SUS201

|

201

|

--

|

--

|

|

1Cr18Mn8Ni5N

|

SUS202

|

202

|

--

|

--

|

|

--

|

--

|

S20200

|

284S16

|

--

|

|

2Cr13Mn9Ni4

|

--

|

--

|

--

|

--

|

|

1Cr17Ni7

|

SUS301

|

301

|

--

|

--

|

|

--

|

--

|

S30100

|

301S21

|

X12CrNi177

|

|

1Cr17Ni8

|

SUS301J1

|

--

|

--

|

X12CrNi177

|

|

1Cr18Ni9

|

SUS302

|

302

|

302S25

|

X12CrNi188

|

|

1Cr18Ni9Si3

|

SUS302B

|

302B

|

--

|

--

|

|

Y1Cr18Ni9

|

SUS303

|

303

|

303S21

|

X12CrNiS188

|

|

Y1Cr18Ni9Se

|

SUS303Se

|

303Se

|

303S41

|

--

|

|

0Cr18Ni9

|

SUS304

|

304

|

304S15

|

X2CrNi89

|

|

00Cr19Ni10

|

SUS304L

|

304L

|

304S12

|

X2CrNi189

|

|

0Cr19Ni9N

|

SUS304N1

|

304N

|

--

|

--

|

|

00Cr19Ni10NbN

|

SUS304N

|

XM21

|

--

|

--

|

|

00Cr18Ni10N

|

SUS304LN

|

--

|

--

|

X2CrNiN1810

|

|

1Cr18Ni12

|

SUS305

|

S30500

|

305S19

|

X5CrNi1911

|

|

[0Cr20Ni10]

|

SUS308

|

308

|

--

|

--

|

|

0Cr23Ni13

|

SUS309S

|

309S

|

--

|

--

|

|

0Cr25Ni20

|

SUS310S

|

310S

|

--

|

--

|

|

0Cr17Ni12Mo2N

|

SUS315N

|

316N,S31651

|

--

|

--

|

|

0Cr17Ni12Mo2

|

SUS316

|

316

|

316S16

|

X5CrNiMo1812

|

|

00Cr17Ni14Mo2

|

SUS316L

|

316L

|

316S12

|

X2CrNiMo1812

|

|

0Cr17Ni12Mo2N

|

SUS316N

|

316N

|

--

|

--

|

|

00Cr17Ni13Mo2N

|

SUS316LN

|

--

|

--

|

X2CrNiMoN1812

|

|

0Cr18Ni12Mo2Ti

|

--

|

--

|

320S17

|

X10CrNiMo1810

|

|

0Cr18Ni14Mo2Cu2

|

SUS316J1

|

--

|

--

|

--

|

|

00Cr18Ni14Mo2Cu2

|

SUS316J1L

|

--

|

--

|

--

|

|

0Cr18Ni12Mo3Ti

|

--

|

--

|

--

|

--

|

|

1Cr18Ni12Mo3Ti

|

--

|

--

|

--

|

--

|

|

0Cr19Ni13Mo3

|

SUS317

|

317

|

317S16

|

--

|

|

00Cr19Ni13Mo3

|

SUS317L

|

317L

|

317S12

|

X2CrNiMo1816

|

|

0Cr18Ni16Mo5

|

SUS317J1

|

--

|

--

|

--

|

|

0Cr18Ni11Ti

|

SUS321

|

321

|

--

|

X10CrNiTi189

|

|

1Cr18Ni9Ti

|

--

|

--

|

--

|

--

|

|

0Cr18Ni11Nb

|

SUS347

|

347

|

347S17

|

X10CrNiNb189

|

|

0Cr18Ni13Si4

|

SUSXM15J1

|

XM15

|

--

|

--

|

|

0Cr18Ni9Cu3

|

SUSXM7

|

XM7

|

--

|

--

|

|

1Cr18Mn10NiMo3N

|

--

|

--

|

--

|

--

|

|

1Cr18Ni12Mo2Ti

|

--

|

--

|

320S17

|

X10CrNiMoTi1810

|

|

00Cr18Ni5Mo3Si2

|

--

|

S31500

|

--

|

3RE60(瑞典)

|

|

0Cr26Ni5Mo2

|

SUS329J1

|

--

|

--

|

--

|

|

1Cr18Ni11Si4AlTi

|

--

|

--

|

--

|

--

|

|

1Cr21Ni5Ti

|

--

|

--

|

--

|

--

|

|

0Cr13

|

SUS410S

|

S41000

|

--

|

X7Cr13

|

|

1Cr13

|

SUS410

|

410

|

410S21

|

X10Cr13

|

|

2Cr13

|

SUS420J1

|

420

|

420S29

|

X20Cr13

|

|

--

|

--

|

S4200

|

420S27

|

--

|

|

3Cr13

|

SUS420J2

|

--

|

420S45

|

--

|

|

3Cr13Mo

|

--

|

--

|

--

|

--

|

|

3Cr16

|

SUS429J1

|

--

|

--

|

--

|

|

1Cr17Ni2

|

SUS431

|

431

|

431S29

|

X22CrNi17

|

|

7Cr17

|

SUS440A

|

440A

|

--

|

--

|

|

11Cr17

|

SUS440C

|

440C

|

--

|

--

|

|

8Cr17

|

SUS440B

|

44013

|

--

|

--

|

|

1Cr12

|

--

|

--

|

--

|

--

|

|

4Cr13

|

SUS420J2

|

--

|

--

|

X4DCr13

|

|

9Cr18

|

SUS440C

|

440C

|

--

|

X105CrMo17

|

|

9Cr18Mo

|

SUS440C

|

440C

|

--

|

--

|

|

9Cr18MoV

|

SUS440B

|

440B

|

--

|

X90CrMoV18

|

|

0Cr17Ni4Cu4Nb

|

SUS630

|

630

|

--

|

--

|

|

0Cr17Ni7Al

|

SUS631

|

631

|

--

|

--

|

|

--

|

--

|

S17700

|

--

|

X7CrNiAl177

|

|

0Cr15Ni7Mo2Al

|

--

|

632

|

--

|

--

|

|

--

|

--

|

S15700

|

--

|

--

|

|

00Cr12

|

SUS410

|

--

|

--

|

--

|

|

0Cr13Al[00Cr13Al]

|

SUS405

|

405

|

--

|

--

|

|

--

|

--

|

S40500

|

405S17

|

X7CrAl13

|

|

1Cr15

|

SUS429

|

429

|

--

|

--

|

|

1Cr17

|

SUS430

|

430

|

--

|

--

|

|

--

|

--

|

S43000

|

430S15

|

X8Cr17

|

|

[Y1Cr17]

|

SUS430F

|

430F

|

--

|

--

|

|

--

|

--

|

S43020

|

--

|

X12CrMoS17

|

|

00Cr17

|

SUS430LX

|

--

|

--

|

--

|

|

1Cr17Mo

|

SUS434

|

434

|

--

|

--

|

|

--

|

--

|

S43400

|

434S19

|

X6CrMo17

|

|

00Cr17Mo

|

SUS436L

|

--

|

--

|

--

|

|

00Cr18Mo2

|

SUS444

|

--

|

--

|

--

|

|

00Cr27Mo

|

SUSXM27

|

XM27

|

--

|

--

|

|

--

|

--

|

S44625

|

--

|

--

|

|

00Cr30Mo2

|

SUS447J1

|

--

|

--

|

--

|

|

1Cr12

|

SUS403

|

403,S40300

|

403S17

|

--

|

|

1Cr13Mo

|

SUS410J1

|

--

|

--

|

--

|

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。

機械類則有對刀具加工非常有幫助的冷風槍、渦流管槍,並有最新設計和技術的粉末成型機。

碧威是在刀具製造及機械工具業界中具有足夠水準的製造供應商!

willy

9 octobre 2012

2

09

/10

/octobre

/2012

04:44

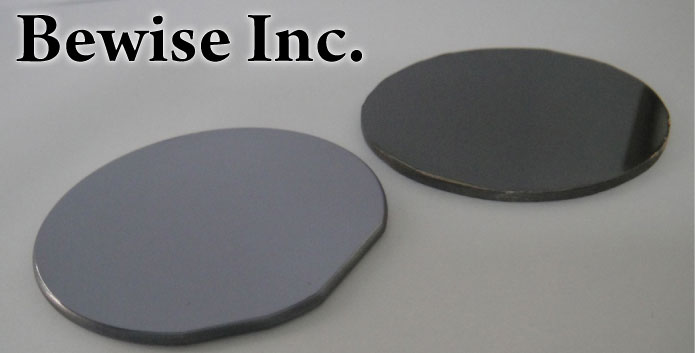

許多難加工材料應用廣泛,其中難加工材料,如不銹鋼中Cr和Ni含量較高,Cr雖能提高不銹鋼的強度和韌性,但增加了不銹鋼與刀具的粘結傾向;Ni可起到穩定組織的作用,但組織塑性大,容易引起加工硬化,採用鎢鈷類硬質合金刀具進行加工,但加工效果並不十分理想。

碧威不銹鋼專用切削刀具是以最新金屬陶瓷材料製作而成,針對成分內含鎳18%以上的難切削材而開發,擁有更好的抗折強度及濕式切削,加工時有更優越的耐損性和穩定性,在加工不銹鋼切削壽命更是鎢鋼刀具5倍以上且在切削表面具有優異的表現。

金屬陶瓷材質刀具切削特性:

- 濕式切削加工時,能具有穩定的切削性能(耐熱衝擊性的提昇)

- 較優越於以往奈米鎢鋼材料種類的耐損性和耐摩耗性

金屬陶瓷材質刀具切削特性:

- 切削刃有再磨自銳效應

- 化學性能穩定性

- 刀片上無浸潤效應

- 刀具其他部分材料向切削轉移可以忽略不計等也是其優點

- Co用作金屬粘結物,取代了Ni與Co混合物,無污染

- 更高的加工安全性

- 應用領域更廣闊

- 保持表面光潔度與精度的能力更強

- 斷續加工能力加強

不同材質刀具之切削測試:

切削方式:不加油、水、切削液(乾式切削)及常溫下切削等條件

|

切削材料

|

不銹鋼

|

|

材料尺寸

|

100*100mm

|

|

主軸轉速

|

5000

|

|

進給速率

|

600

|

|

切削總長

|

850mm

|

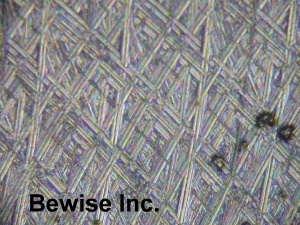

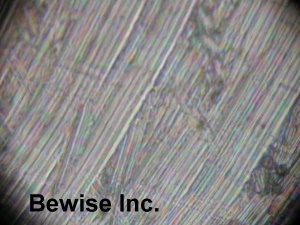

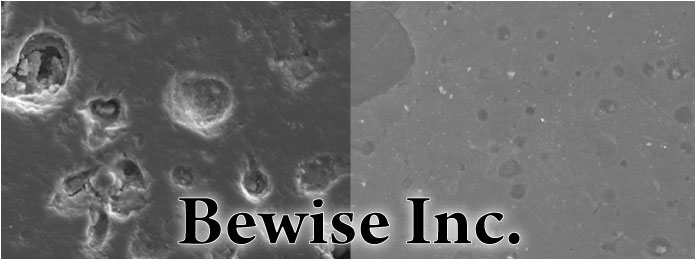

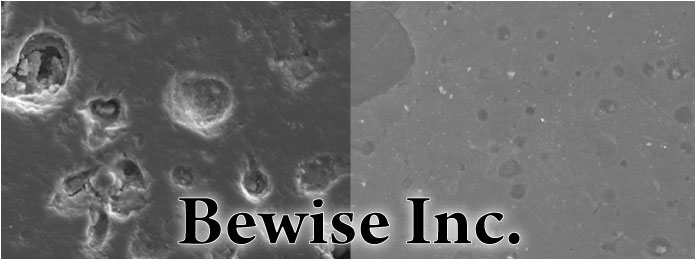

2刃平銑刀/HSS Co 8%-HSS刀具切削刀痕金相圖

4刃圓鼻銑刀/奈米鎢鋼-鎢鋼刀具切削刀痕金相圖

4刃平銑刀/極細超微粒鎢鋼-鎢鋼刀具切削刀痕金相圖

4刃圓鼻銑刀/超微粒鎢鋼-鎢鋼刀具切削刀痕金相圖

金屬陶瓷材質刀具之切削測試:

切削方式:不加油、水、切削液(乾式切削)及常溫下切削等條件

刀具規格:直徑8mm/R0.5/刃長20mm/全長60mm/螺旋角35度

|

切削材料

|

不銹鋼

|

|

材料尺寸

|

100*100mm

|

|

主軸轉速

|

5000

|

|

進給速率

|

600

|

|

切削總長

|

3400mm

|

金屬陶瓷刀具切削後初期刀痕金相圖

金屬陶瓷刀具切削後期刀痕金相圖

金屬陶瓷刀具介紹測試報告

willy

6 octobre 2012

6

06

/10

/octobre

/2012

04:19

不鏽鋼(Inox)不像普通鋼那樣容易腐蝕生鏽。鉻是使不銹鋼獲得耐蝕性 的基本元素,鋼中加入鉻、鎳使其表面會產生防鏽的氧化膜,從而保護鋼材本身受到外界環境中的空氣(尤指氧氣 )、水、某些酸、鹼的氧化腐蝕,為了保持不銹鋼所固有的耐腐蝕性,鋼必須含有

12%以上的鉻,除鉻外,常用的合金元素還有鎳、鉬、鈦、鈮、銅、氮等,以滿足各種用途對不銹鋼組織 和性能的要求。

不銹鋼按組織狀態分類 :

|

鐵素體不銹鋼

|

奧氏體不銹鋼

|

奧氏體 - 鐵素體

雙相不銹鋼

|

馬氏體不銹鋼

|

|

主要成分

|

含鉻12%~30%。其耐蝕性、韌性和可焊性隨含鉻量的增加而提高,

|

含鉻大於18%,還含有 8%左右的鎳及少量鉬、鈦、氮等元素。

|

奧氏體和鐵素體組織各約占一半的不銹鋼。在含C較低的情況下,Cr含量在18%~28%,Ni 含量在3%~10%。有些鋼還含有Mo、Cu、Si、Nb、Ti,N等合金元素。

|

鉻含量不低於12%(一般在12%~18%),碳含量較高

|

|

特性

|

耐氯化物應力腐蝕性能優於其他種類不銹鋼。屬於這一類的有鐵素體不銹鋼因為含鉻量 高,耐腐蝕性能與抗氧化性能均比較好,但機械性能與工藝性能較差,多用於受力不大的耐酸結構及作抗氧化鋼使 用。

|

綜合性能好,可耐多種介質腐蝕。0Cr19Ni9鋼的wC<0.08%,鋼號中標記為“0”。這類 鋼中含有大量的Ni和Cr,使鋼在室溫下呈奧氏體狀態。這類鋼具有良好的塑性、韌性、焊接性和耐蝕性能。

|

兼有奧氏體和鐵素體不銹鋼的特點,與鐵素體相比,塑性、韌性更高,無室溫脆性,耐 晶間腐蝕性能和焊接性能均顯著提高,同時還保持有鐵素體不銹鋼的475℃脆性以及導熱係數高,具有超塑性等特點 。

|

強度高,但塑性和可焊性較差。 因含碳較高,故具有較高的強度、硬度和耐磨性,但耐 蝕性稍差,用於力學性能要求較高、耐蝕性能要求一般的一些零件上,如彈簧、汽輪機葉片、水壓機閥等。這類鋼 是在淬火、回火處理後使用的。

|

|

常用鋼號

|

Crl7、Cr17Mo2Ti、Cr25、Cr25Mo3Ti、Cr28等。

|

1Cr18Ni9、0Cr19Ni9等。

|

14Cr18Ni11Si4AlTi、022Cr19Ni5Mo3Si2N、12Cr21Ni5Ti等

|

1Cr13、3Cr13等

|

不銹鋼一般特性:

- 表面美觀以及使用可能性多樣化

- 耐腐蝕性能好,比普通鋼長久耐用

- 耐腐蝕性好

- 強度高,因而薄板使用的可能性大

- 耐高溫氧化及強度高,因此能夠抗火災

- 常溫加工,即容易塑性加工

- 因為不必表面處理,所以簡便、維護簡單

- 清潔,光潔度高

- 焊接性能好

不銹鋼切削加工特性

-

加工硬化嚴重:在不銹鋼中,以奧氏體和奧氏體+鐵素體不銹鋼的加工硬 化現象最為突出。不銹鋼的塑性大,塑性變形時品格歪扭,強化係數很大且奧氏體不夠穩定,在切削應力的作用下 ,部分奧氏體會轉變為馬氏體;再加上化合物雜質在切削熱的作用下,易於分解呈彌散分佈,使切削加工時產生硬 化層。前一次進給或前一道工序所產生的加工硬化現象嚴重影響後續工序的順利進行。

-

切削力大:不銹鋼在切削過程中塑性變形大,尤其是奧氏體不銹鋼(其伸 長率超過45號鋼的1.5倍以上),使切削力增加。同時,不銹鋼的加工硬化嚴重,熱強度高,進一步增大了切削抗力 ,切屑的捲曲折斷也比較困難。

-

切削溫度高:切削時塑性變形及與銑刀間的摩擦都很大,產生的切削熱多;加上不銹鋼的 導熱係數約為45號鋼的?~?,大量切削熱都集中在切削區和刀—屑接觸的介面上,散熱條件差。

- 切屑不易折斷、易粘結:不銹鋼的塑性、韌性都很大,車加工時切屑連綿不斷,不僅影響操 作的順利進行,切屑還會擠傷已加工表面。在高溫、高壓下,不銹鋼與其他金屬的親和性強,易產生粘附現象,並 形成積屑瘤,既加劇刀具磨損,又會出現撕扯現象而使已加 工表面惡化。含碳量較低的馬氏體不銹鋼的這一特點更為明顯。

-

刀具易磨損:切削不銹鋼過程中的親和作用,使刀 —屑間產生粘結、擴散,從而使刀具產生粘結磨損、擴散磨損,致使刀具前刀面產生月牙窪,切削刃還會形成

微小的剝落和缺口;加上不銹鋼中的碳化物(如TiC)微粒硬度很高,切削時直接與刀具接觸、摩擦,擦傷刀具,還有 加工硬化現象,均會使刀具磨損加劇。

-

線膨脹係數大:不銹鋼的線膨脹係數約為碳素鋼的1.5倍,在切削溫度作 用下,工件容易產生熱變形,尺寸精度較難控制。

willy

22 août 2012

3

22

/08

/août

/2012

04:22

Selection of woodworking cutters

-

identify the main technical parameters of the cutter

Main parameters:outer diameter, machining thickness, and the center diameter.

Other technical parameters: number of teeth, the direction of rotation, rotation speed, feed rate, clamping way, and cutter material.

-

Choose the structure type of cutter

According the request and characteristics of cutting object, and consideration from both the technical and economic aspects, select the whole cutters or welding cutters, assembly cutters, and combination cutter.

-

The choice of the cutter rotation direction

Cutter rotation direction is determined in accordance with the direction of rotation of the processing machinery spindle and the tool axis and the feed of the work

piece relative position of the whole cutter, or assembling cutter, the inclination of the cutting blade relative to cutter radius determines the rotation of the cutter

direction.

-

Selection of cutting amount of end mills

Cutting amount of end mills are including cutting speed, feed speed of work material, and depth of milling. Cutting speed depends on the rpm and the radius of the end mills ..

feed rate depends on the requirements of cutting surface .. the surface roughness of work material largely depends on the feed rate per tooth during cutting process, too much feed will cause

too rough surface of work piece; too small feed will cause burnt phenomenon on the surface, so the feed rate must be appropriate.

-

Operation stability of end mills

The stability of the cutter operation is to ensure that the basis of the machining accuracy and surface quality .. including two aspects: one is cutter excited vibration in machining due to

external forces; the other is that cutter happens deformation by external forces.

-

Safety of milling process

The safety of the milling cutter includes the limitation of rotation speed, the limitation of chip thickness, height restrictions of molding cutter contour and the thickness of assembly cutter,

and stretched limit.

Cutting timber is characterized by high speed cutting, the rotation speed of the milling cutters mostly above 3000 rpm. High speed cutting for timber brings high productivity and smooth surface

.., it also brings a series of security problems. Therefore, when the spindle speed up to 9000 rpm, besides the cutter which diameter smaller than 16mm, it should prohibit to use assembly

cutters and do strict testing and inspection for welding cutter.

It is necessary to limit chip thickness for avoiding overload of cutters. For end mills, the clamping method, cutter height, and thickness of work piece are with close relationship. When you

ensure the thickness of work piece, mill diameter, and center diameter, the height of cutter reflects its own strength, stiffness, and capacity of cutting resistance. The height must be limited

to ensure the safety of cutter usage.

The design point of welding end mills is clamping problem. No matter the body is cylindrical or disc-type, the blade

clamp form must be guaranteed to provide sufficient clamping force to resist rotation centrifugal force .

Reference sources – China Timber Net

Bewise Inc., being a professional manufacturer of various cutting tools, is endeavoring to make

excellent products. We are very experienced in custom-made tools, and good at solving customers’ problems when they meet difficulties and troubles. Through everlasting research and practices, we

understand thoroughly about different materials of cutters and cutting tools.

BW's popular products for tool series including circular saw, carbide cutting tool,

saw blade, wood saw blade, special tool,side milling cutter, …etc; For machines we have spiral tube cooler, cutter grinder, and the latest design and advanced powder forming machine / pelletizer. Bewise is a superior manufacturer and supplier of cutter

production and machinery industry.

willy

22 août 2012

3

22

/08

/août

/2012

04:20

超精密加工是指加工誤差小於0.01μm、表面粗糙度小於Ra0.02μm

的加工,又稱之為亞微米級加工。現在,超精密加工已進入納米級,稱之為納米加工。用於製造高精度高表面品質的零件,如大型積體電路的矽片,不僅要求極高的平面度,極小的表面粗糙度,而且要求表面無變質層、無劃傷。光學平晶、量塊、石英振子基片平面,除要求極高平面度、極小表面粗糙度外,還要求兩端面嚴格平行。

拋光研磨方法:

|

研磨方法

|

磨料

|

研磨工具

|

研磨液

|

研磨方式

|

加工機理

|

加工對象

|

|

超精密研磨

|

各種維細磨料

|

鑄鐵

玻璃

陶瓷

|

機油

煤油

水溶液

|

手工研磨

機械研磨

|

以磨料的機械作用為去除加工余量

|

各種形位及尺寸精度高的硬脆材料零件

|

|

超精密拋光

|

各種微細磨料、軟質磨料

|

軟質研具、瀝青等

|

過濾水或蒸餾水

|

透鏡、平鏡研磨機,帶修整輪,加工運動平穩

|

光學零件、石英振子、玻璃等

|

液中研磨

、拋光

|

微細磨料

|

合成樹脂

|

過濾水或蒸餾水

|

研磨運動在液體中進行

|

以磨料的機械作用為主,加上液體的冷卻,分散磨料作用

|

矽片等電子材料

|

化學研磨

、拋光

|

微細磨料

|

無紡織等

|

純水或水溶液

|

研磨壓力大研磨速度高

|

以磨料的機械作用去除化學反應生成物

|

矽等

|

|

軟質磨料

|

玻璃板

|

藍寶石基板

|

機械作用的超精密研磨:

|

超精密研磨種類

|

加工原理

|

|

機械研磨

|

依靠微細磨粒的機械作用對被加工表面進行微量去除,達到高精度的加工表面。

|

|

彈性發射加工

|

加工時使用聚氨脂球作加工頭,在高速旋轉的加工頭與被加工工件表面之間加上含有微細磨粒(0.1~0.01μm)的研磨液,並產生一定的壓力。通過高速旋轉的加工頭所產生的高速氣流及離心力,使磨粒衝擊或擦過工件表面,產生彈性破壞物質的原子結合,從而去除工件表面的材料。

|

|

浮動研磨

|

利用流體力學原理使拋光器與工件浮離,在拋光器的工件表面做出了若干楔槽,當拋光器高速旋轉時,由於油楔的動壓作用使工件或拋光器浮起,其間的磨粒就對工件表面進行拋光。

|

|

磁力研磨

|

磁力研磨是利用磁場將磁性磨料聚集在工件與磁極間之工作間隙內,這些聚集的磁性磨料在磁場的作用下形成一束撓性的磁力刷(magnetic brush),同時產生研磨壓力作用在工件表面上,再藉由工件的旋轉與軸向振動,使磁性磨粒與工件表面之間產生相對運動,而達到精密拋光的效果

|

|

電解磁力研磨

|

電流電壓的陽極接工件,陰極接工具,陰極接欲去除毛刺的工件部位。電解液由泵驅動後經陰極流過陽極工件的毛刺部位到達回流槽。工件以一定的速度旋轉,同時作軸向振動。在垂直於工件軸線及電力線的平面方向上加直流強磁場,在磁場中填入游離狀的磁性磨料,由磁磨料組成的“磨料刷”快速衝擊件表面,去除突起的毛刺和實現光整加工。

|

|

ELID研磨

|

電子零件等功能材料之進步是有目共睹的,但對於各種素材零件之加工精度要求則是愈來愈嚴格。其加工技巧之磨料加工技術的研磨、拋光方面,對於高效率、高精度、高品位、超精密、自動化等之期望也很高,滿足其要求的加工技術之一為ELID研磨法。

ELID研磨法為金屬結合砂輪的削銳方法之一,利用電氣化學作用所產生之電解溶出現象,在研磨加工中也可以連續地進行削銳,以保持穩定的銳利度。

|

機械+化學作用的超精密研磨:

|

超精密研磨種類

|

加工原理

|

|

化學機械研磨(CMP)

|

CMP 指化學機械研磨 (Chemical Mechanical Polishing),或稱為化學機械平坦化 (Chemical Mechanical Planarization)。研磨液會與基材產生化學反應,反應生成物以力作用方式去除。利用作用力促進化學反應。

|

|

機械化學拋光(MCP)

|

磨料和基材之間由於力作用產生化學反應,在表面形成反應生成物,以力作用方式去除。利用作用力促進化學反應。

|

|

超音波振動研磨

|

超音波震動工具頭的端面與工件表面保持一固定的間隙δ,並在其間充以微細磨粒工作液,當超音波振動工具以一定的頻率振動時,帶動微細磨粒衝擊工件表面,從而對工件表面進行研磨。

|

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。

機械類則有對刀具加工非常有幫助的冷風槍、渦流管槍,並有最新設計和技術的粉末成型機。

碧威是在

willy

15 août 2012

3

15

/08

/août

/2012

03:01

Basis of woodworking cutter

-

nature of working material

There are hard wood and wood composites material. And it may be divided into soft wood, hard wood and modified wood; wood composite materials, including plywood, laminated veneer lumber,

particleboard, oriented strand board, wafer board, gypsum particle board, cement particle board, hardboard, medium density fiberboard, high density fiberboard, block board, glued timber, etc.

Wood or wood composite work piece are needed to process the single-or double-sided decorative veneer progress.

-

the cutting direction

According to the cutting blade and relative direction of the wood, it is divided into vertical, horizontal, side and vertical side, aspect and cross-side cutting.

-

rotation direction and feed direction of cutter

In accordance with the rotation of the machine tool axis direction and wood work piece feeding direction, determine the direction of the tool blade tilt.

-

the cutter and the stability of work piece

Include several aspects of the tool and the work piece in the cutting process stability, the stability means smooth and no beating during

process. The solution is reducing the center gravity of work piece and increasing the contact area.

-

quality request of working surface

Surface quality including surface roughness, geometric size and accuracy of shape position.

Reference sources – China Timber Net

Bewise Inc., being a professional manufacturer of various cutting tools, is endeavoring to make

excellent products. We are very experienced in custom-made tools, and good at solving customers’ problems when they meet difficulties and troubles. Through everlasting research and practices, we

understand thoroughly about different materials of cutters and cutting tools.

BW's popular products for tool series including circular saw, carbide cutting tool,

saw blade, wood saw blade, special tool,side milling cutter, …etc; For machines we have spiral tube cooler, cutter grinder, and the latest design and advanced powder forming machine / pelletizer. Bewise is a superior manufacturer and supplier of cutter

production and machinery industry.

willy

15 août 2012

3

15

/08

/août

/2012

02:44

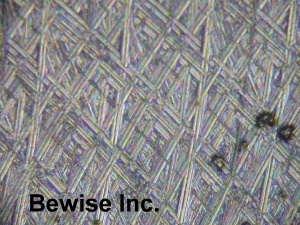

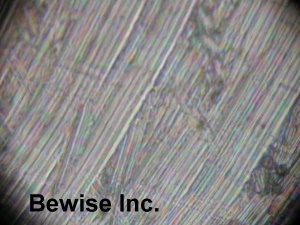

曲軸在發動機內是一個高速旋轉的長軸,其受力條件相當複雜,除了旋轉品質的離心力外,還承受 週期性變化的氣體壓力和往復慣性力的共同作用,為保證工作穩定性,曲軸必須要有足夠的強度和剛度,各工作表面要耐 磨而且潤滑良好。

曲軸的典型加工順序為:

銑兩端面→鑽中心孔→粗車→精車→銑削→熱處理→磨削加工等。

曲軸工件表面在磨削加工以後,出現不穩定的表面層會在每個軸頸和圓角處,造成曲軸壽命的縮減,利用 曲軸砂帶拋光加工技術,在確保工件精度和尺寸精度的前提下,去掉不穩定的表面層,以形成正常尺寸的油膜厚度及具有 良好的油膜剛性。

曲軸砂帶拋光在加工中,選擇合適的砂帶是保證拋光加工的關鍵,砂帶通常採用靜電植砂方式,每顆砂粒都

有最佳的定位方向,以形成鋒利的砂刃。砂帶的切削過程分為磨削和拋光 兩個階段,在加工初期,砂帶起的是磨削作用,在工件旋轉和軸向位移的複合

運動中,將表面磨痕的谷峰磨平,隨著砂粒微刃被磨平,切削力隨之增大,砂粒被剝離基帶,同較粘稠的拋光介質形成研 磨劑,這時加工由磨削轉入拋光階段。

細微性分佈均勻,棱角向上,可 以保持均勻持續的切削力以及最佳的表面精度。

在對曲軸表面進行拋光時,拋光加工不會由表面張力和微觀裂紋而形成軟表皮,能更確切地所是顯露出 本來的組織結構,並且明顯改善了曲軸零件的性能。通過砂帶拋光,使工件表面形成一種由相互交錯規則的網紋組成的平 臺結構,這種結構有利於不同元件的配合精度。這些網紋可吸納潤滑液,並改善曲軸零件的摩擦性能。

此外,特別對鑄造工件來講要去除所謂的薄殼層,但在經過磨削後,此薄殼層將鑄造氣孔封閉了,從而 導致在發動機運行時加劇磨損,通過砂帶拋光可去除薄殼層,並使氣孔的邊緣倒圓,因而不會撕破已形成的油膜。

參考資料來源: 曲軸加工工藝、曲??光技?的?展 文章

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。

機械類則有對刀具加工非常有幫助的冷風槍、渦流管槍,並有最新設計和技術的粉末成型機。

碧威是在刀具製造及機械工具業界中具有足夠水準的製造供應商!

willy

25 juillet 2012

3

25

/07

/juillet

/2012

05:19

Following on last introduction of end

mill selection, now we continue to introduce the classification of cutter shape and application.

There are square end mill, side cutter, angle cutter, shape cutter, end mill, T-slot cutter, semi-moon key seat cutter, dovetail cutter , as well as face milling cutter.

-

Plain milling cutter:

Make cutting edge from a cylindrical rod to mill the plane of work piece, that we called flat cutter .. a cutting flute parallel to axis which is proper for light milling, because all the

chips will be into the chip slot which will make the cutter beat, it is not suitable for heavy cutting ..) diagram and (c) diagram of the cutting edge of the spiral can have more than one

cutting edge contact with the face milling cutting situation, so it’s more stable ..) diagram of the spiral angle have a better cutting effect since its helix is bigger, and it may reduce the

milling vibration, resulting in a smooth surface, it can be used in heavy cutting or machining hard materials ..) helix angle is smaller, which is suitable for cutting middle amount of

milling or fine cutting surface of work piece.

(a)Light cutting

plain milling cutter

|

(b)Heavy cutting

plain milling cutter

|

(c)Finishing cutting

plain milling cutter

|

|

|

|

-

Side milling cutter:

Side cutter names from its side with cutting edge, divided into flat side milling cutter,

hemi-cutter, staggered blade side cutter and interlocking side cutter four types according to the distribution of blades, as below, The flat side milling cutter (as shown in (a)) with edges

in circumference and both sides of the blade can be used to slot, mill plane and ride milling. Hemi-cutter (as shown (b) below) with edges on the circumference and single side, which is good

for heavy milling.. the blade could be on the left or right, so if the left and right side of the cutter, in the middle set a flat cutter, you can make milling work. Turn staggered cutting

edge on both sides of the surface, said helix angle relative staggered blade side cutter (see the (c) below), allows milling force to reduce vibration and beat, always used in high-speed

groove and deep feed milling. The following diagram (d) shows the interlocking side cutter, combine the left and right side of the cutter and the blades of both sides is also relatively,

which axial thrust offset each other to do right groove milling work .

|

(a)Flat side milling cutter

|

(b)Hemi-cutter

|

(c)Staggered blade side cutter

|

(d)Interlocking side cutter

|

|

|

|

|

-

Angular cutter:

Cutting edge is neither parallel nor perpendicular to the cutter axis called the angle cutters .. unilateral angle cutters and bilateral angle cutters, as shown below, used for milling

angular surfaces, such as the V-shaped groove slot, serrated, beveled and hinged blade teeth.

Unilateral angle cutters cutting edge cutting edge of the cone surface, flat on the cutting edge is the cutter cone into perspective, but also in the left or right side (as shown in a) ..

term point of view; bilateral angle cutters, cutting edge on the two intersect the cone on both sides of the angle can be equal or not equal (as shown below (b) below) .. edge angle are equal

while the angle of the size of the call.

|

(a)Unilateral angle cutters

|

(b)Bilateral angle cutters

|

|

|

-

Metal slitting saw:

For milling slots or cutting metal, shown as below:

-

Formed cutter:

According to shape of cutting edge, milling its the opposite shape of the work piece, suitable for mass production, shown three popular types as below:

|

(a)Convex-type cutter

|

(b)Concave cutter

|

(c)Gear-type cutter

|

|

|

|

-

End mill:

Cutting edge on the face and on the periphery of the end mill. Just like drill bit and erection of flat

end mills, hence it is often used in milling plane, groove, and contour.

-

T-slot cutter:

Cutting edges in the both sides and the circumferential surface, and has a standard taper shank into the connector then put into the spindle .. cutters or side cutters milling a vertical slot

on the work piece, and then use the T-slot cutters at the bottom milling to create a wide horizontal slot, it’s the T-slot.

-

Woodruff keyseat cutter:

Similar to the side milling cutter, but only with cutting edges on the circumferential surface, and it has a handle, used for milling half-moon shape key set of work piece.

-

Dovetail milling cutter:

For machining dovetail set and groove.

-

Face milling cutter:

Face milling cutter is much like the sets of shell-side cutter, face milling cutter diameter 150 nm or more sets of rods mounted in the milling machine spindle mouth, face milling cutter for

milling flat similar to its work planer .. knife circle cutter for milling work on the plane cutter for fine cut light repair work.

|

(a)HSS face milling cutte

|

(b)WC face milling cutte

|

|

|

Conclusion:

-

General cutter materials and usage occasion as follows

-

High-speed steel cutters:for general purposes, the most widely used.

-

Carbide cutter:for high speed cutting.

-

Non-ferrous metal casting alloy cutter:suitable for heavy cutting.

-

Plain milling cutter

- Straight shank end mill

- Taper shank end mill

-

Common end mills:

- Convex-type cutter

- Concave cutter

- Gear-type cutter

- Dove tailstock cutter

- Semi-moon key cutter

article reference - Vocational Training Council

Bewise Inc., being a professional manufacturer of various cutting tools, is endeavoring to make

excellent products. We are very experienced in custom-made tools, and good at solving customers’ problems when they meet difficulties and troubles. Through everlasting research and practices, we

understand thoroughly about different materials of cutters and cutting tools.

BW's popular products for tool series including circular saw, carbide cutting tool,

saw blade, wood saw blade, special tool,side milling cutter, …etc; For machines we have spiral tube cooler, cutter grinder, and the latest design and advanced powder forming machine / pelletizer. Bewise is a superior manufacturer and supplier of cutter

production and machinery industry.

willy

25 juillet 2012

3

25

/07

/juillet

/2012

02:58

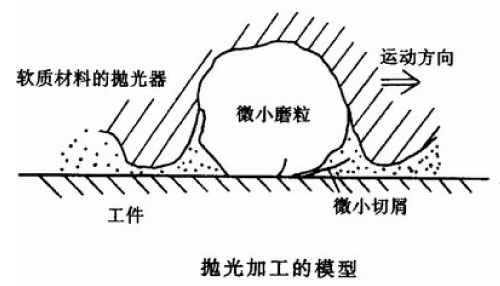

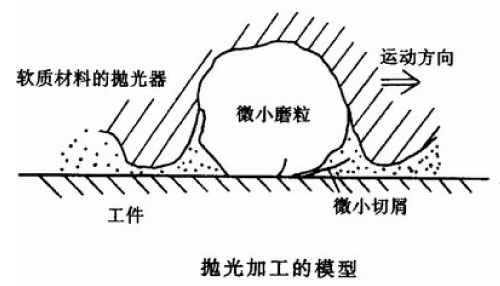

研磨拋光(Polishing or Lapping)是使工件產生平滑鏡面的超精密研磨技術,其目的在於使表面粗糙度及平坦度到達一定的可容許範圍,常被廣泛的使用在硬脆金屬、陶瓷、玻璃及 晶圓等材料表面的精密加工。

研磨

研磨工作方式:

研磨加工通常使用1μm到幾十μm磨粒和鑄鐵等硬質材料的研具。

-

磨粒在工件與研具之間進行轉動

- 由研具面支撐磨粒研磨加工面

- 由工件支撐磨粒研磨加工面

研磨特性:

-

硬脆材料的研磨

- 微小破碎痕跡構成的無光澤面。

- 磨粒不是作用於鏡面而是作用在有凸凹和裂紋等處的表面上,並產生磨屑。

-

金屬材料的研磨

- 表面沒有裂紋。

- 對於鋁材等軟質材料,研磨時有很多磨粒被壓入材料內;對刀具和塊規等淬火工具鋼等可確保有塊規那樣的光澤表面。

拋光

拋光工作方式:

- 使用<1μm的微細磨粒。

- 軟質材料拋光墊:瀝青、石蠟、合成樹脂和人造革等。

- 微小的磨粒被拋光器彈性地夾持研磨工件。因而,磨粒對工件的作用力很小,即使拋光脆性材料也不會發生裂紋。

研磨特性:

- 由磨粒進行的機械拋光可塑性地生成切屑。但是它僅利用極少磨粒強制壓入產生作用。

- 借助磨粒和拋光器與工件流動摩擦使工件表面的凸因變平。

- 在加工液中進行化學性溶析。

- 工件和磨粒之間有直接的化學反應而有助於上述現象。

碧威為專業的刀具,銑刀,鎢鋼,切削刀具製造商,致力於製造優秀的產品,在客製化刀具方面的經驗十分豐富,並擅於幫助客戶解決各式各樣之刀具切削面臨之問題,對各種刀具材質切削刀具鍍模都非常瞭解透徹,可選用常見的鎢鋼及高速鋼或是近來詢問度極高的鑽石刀具。

碧威銑刀熱門產品為圓鋸片、鎢鋼刀、鋸片、木工鋸片、鎢鋼刀具及側銑刀。

機械類則有對刀具加工非常有幫助的冷風槍、渦流管槍,並有最新設計和技術的粉末成型機。

碧威是在刀具製造及機械工具業界中具有足夠水準的製造供應商!

willy

4 juillet 2012

3

04

/07

/juillet

/2012

03:23

There are lots of metal products around us in our life, but we all know how they are produced?

There are many processing methods to make metal, cutting is the major one among them.

Firstly, let's learn about cutting tool and machining! We often talk about cutting tool. However, what is

cutting tool?

At first, we should think about cutting tools around us.

There are a number of cutting tools in our lives .., kitchen knife, knives and other cutting tools (rub the radish), paper knife and pencil sharpener of the

table, the saw and plane of tool box and so on, these also belong to cutting tools. Cutters change shape of objects through cutting, and

produce cutting debris.

We should have understood that cutting tool is the tool that may change the shape into our expected form through cutting. The cutters in life includes fruit

knife, vegetable knife, and cutting saws for wood, etc.

Reference source:mitsubishicarbide.net

willy