Bewise Inc. www.tool-tool.com Reference source from the

internet.

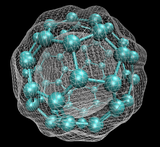

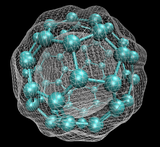

A fullerene is any molecule composed entirely of carbon, in the form of a hollow sphere, ellipsoid, or tube.

Spherical fullerenes are also called buckyballs, and cylindrical ones are called carbon nanotubes or buckytubes.

Fullerenes are similar in structure to graphite, which is composed of stacked graphene

sheets of linked hexagonal rings; but they may also contain pentagonal (or sometimes heptagonal) rings.

The first fullerene to be discovered, and the family’s namesake, buckminsterfullerene (C60), was prepared in 1985 by

Richard Smalley, Robert Curl, James Heath, Sean O’Brien, and Harold

Kroto at Rice University. The name was an homage to Buckminster

Fuller, whose geodesic domes it resembles. The structure was also identified some five years earlier by Sumio Iijima, from an electron microscope image, where it formed the core of a "bucky onion." Fullerenes have since been found to occur (if rarely)

in nature.

The discovery of fullerenes greatly expanded the number of known carbon allotropes, which

until recently were limited to graphite, diamond, and amorphous carbon such as soot and charcoal.

Buckyballs and buckytubes have been the subject of intense research, both for their unique chemistry and for their technological applications, especially in materials science, electronics, and nanotechnology.

The icosahedral C60H60 cage was mentioned in 1965 as a possible topological structure. The existence of C60 was predicted by Eiji Osawa of Toyohashi University of Technology in 1970. He noticed

that the structure of a corannulene molecule was a subset of a soccer-ball shape, and he hypothesised that a full ball shape could also exist. His idea was reported in Japanese magazines, but

did not reach Europe or the Americas.

Also in 1970, R. W.Henson (then of the Atomic Energy Research Establishment) proposed the structure and made a

model of C60. The evidence for this new form of carbon was very weak and was not accepted, even by his colleagues. The results were never published but were acknowledged in

Carbon in 1999.

With mass spectrometry, discrete peaks were observed corresponding to molecules with the exact mass of sixty or seventy or more carbon

atoms. In 1985, Harold Kroto (then of the University of Sussex), James R. Heath, Sean

O’Brien, Robert Curl and Richard Smalley, from Rice University, discovered C60, and shortly thereafter came to discover the fullerenes. Kroto, Curl, and Smalley were awarded the

1996 Nobel Prize in Chemistry for their roles in the discovery of this class of molecules. C60 and other fullerenes

were later noticed occurring outside the laboratory (e.g., in normal candle soot). By 1991, it

was relatively easy to produce gram-sized samples of fullerene powder using the techniques of Donald Huffman and Wolfgang

Krätschmer. Fullerene purification remains a challenge to chemists and to a large extent determines fullerene prices.

So-called endohedral fullerenes have ions or small molecules incorporated inside the cage atoms. Fullerene is an unusual reactant

in many organic reactions such as the Bingel reaction discovered in 1993.

Carbon nanotubes were recognized in 1991.

Minute quantities of the fullerenes, in the form of C60, C70, C76, and C84 molecules, are produced in nature, hidden in soot and formed by lightning discharges in the atmosphere. In 1992, fullerenes were found in a family of minerals known as Shungites in Karelia, Russia.

In 2010, fullerenes (C60) have been discovered in a cloud of cosmic dust surrounding a distant star 6500 light years away. Using NASA’s Spitzer infrared telescope the scientists spotted the molecules’ unmistakable infrared signature. Sir Harry Kroto, who shared the 1996

Nobel Prize in Chemistry for the discovery of buckyballs commented: "This most exciting breakthrough provides convincing evidence that the buckyball has, as I long suspected, existed since time

immemorial in the dark recesses of our galaxy."

Buckminsterfullerene (C60) was named after Richard

Buckminster Fuller, a noted architectural modeler who popularized the geodesic dome. Since buckminsterfullerenes have a similar shape

to that sort of dome, the name was thought to be appropriate. As the discovery of the fullerene family came after buckminsterfullerene, the shortened name ‘fullerene’ was used to refer

to the family of fullerenes. The suffix “ene” indicates that each C atom is covalently bonded to three others (instead of the maximum of four), a situation that classically would correspond to

the existence of bonds involving two pairs of electrons (“double bonds”).

Since the discovery of fullerenes in 1985, structural variations on fullerenes have evolved well beyond the individual clusters themselves. Examples include:[13]

-

buckyball clusters: smallest member is C20 (unsaturated version of dodecahedrane) and the most common is

C60;

-

nanotubes: hollow tubes of very small dimensions, having single or multiple walls; potential applications in electronics industry;

-

megatubes: larger in diameter than nanotubes and prepared with walls of different thickness; potentially used for the transport of a variety of molecules of different

sizes;[14]

-

polymers: chain, two-dimensional and three-dimensional polymers are formed under high pressure high temperature conditions

-

nano"onions": spherical particles based on multiple carbon layers surrounding a buckyball core; proposed for lubricants;[15]

-

linked "ball-and-chain" dimers: two buckyballs linked by a carbon chain;[16]

-

fullerene rings.[17]

C60 with isosurface of ground state electron density as calculated with DFT

Many association footballs have the same shape as the Buckminsterfullerene C60

[

edit] Buckminsterfullerene

Main article: Buckminsterfullerene

Buckminsterfullerene is the smallest fullerene molecule in which no two pentagons share an edge (which can be destabilizing, as in pentalene).

It is also the most common in terms of natural occurrence, as it can often be found in soot.

The structure of C60 is a truncated (T = 3) icosahedron, which resembles a soccer ball of the type made of twenty hexagons and twelve pentagons, with a carbon atom at the vertices of each polygon and a

bond along each polygon edge.

The van der Waals diameter of a C60 molecule is about 1.1 nanometers (nm).[18] The nucleus to nucleus diameter of a C60

molecule is about 0.71 nm.

The C60 molecule has two bond lengths. The 6:6 ring bonds (between two hexagons) can be considered "double bonds" and are shorter

than the 6:5 bonds (between a hexagon and a pentagon). Its average bond length is 1.4 angstroms.

Silicon buckyballs have been created around metal ions.

A new type of buckyball using boron atoms instead of the usual carbon has been predicted and described in 2007. The B80 structure, with

each atom forming 5 or 6 bonds, is predicted to be more stable than the C60 buckyball.[19] One reason for

this given by the researchers is that the B-80 is actually more like the original geodesic dome structure popularized by Buckminster Fuller which uses triangles rather than hexagons. However,

this work has been subject to much criticism by quantum chemists[20][21] as it was concluded that the predicted Ih symmetric structure was vibrationally unstable and the resulting cage undergoes a

spontaneous symmetry break yielding a puckered cage with rare Th symmetry (symmetry of a volleyball).[20] The number of six atom rings in this molecule is 20 and number of five member rings is 12. There is an

additional atom in the center of each six member ring, bonded to each atom surrounding it.

Another fairly common buckminsterfullerene is C70,[22] but fullerenes with 72, 76, 84 and even up to 100

carbon atoms are commonly obtained.

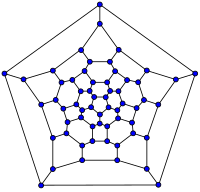

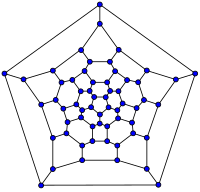

In mathematical terms, the structure of a fullerene is a trivalent convex polyhedron with pentagonal and hexagonal faces. In graph theory, the term fullerene refers to any 3-regular, planar graph with all faces of size 5 or 6 (including the external face). It follows from Euler’s polyhedron formula, V − E + F = 2, (where V, E, F are the numbers of

vertices, edges, and faces), that there are exactly 12 pentagons in a fullerene and V/2 − 10 hexagons.

20-fullerene

(dodecahedral graph)

26-fullerene graph

60-fullerene

(truncated icosahedral graph)

70-fullerene graph

The smallest fullerene is the dodecahedral C20. There are no fullerenes with 22 vertices.[23] The number of fullerenes C2n grows with increasing n = 12, 13, 14, …, roughly in proportion to

n9 (sequence A007894 in OEIS). For instance, there

are 1812 non-isomorphic fullerenes C60. Note that only one form of C60, the buckminsterfullerene alias truncated

icosahedron, has no pair of adjacent pentagons (the smallest such fullerene). To further illustrate the growth, there are 214,127,713 non-isomorphic fullerenes C200, 15,655,672 of

which have no adjacent pentagons.

Trimetasphere carbon nanomaterials were discovered by researchers at Virginia

Tech and licensed exclusively to Luna Innovations. This class of novel molecules comprises 80 carbon atoms (C80) forming

a sphere which encloses a complex of three metal atoms and one nitrogen atom. These fullerenes encapsulate metals which puts them in the subset referred to as metallofullerenes. Trimetaspheres have the potential for use in diagnostics (as safe imaging agents), therapeutics and in organic solar

cells.[citation needed]

This rotating model of a carbon nanotube shows its 3D structure.

Main article: Carbon nanotube

Nanotubes are cylindrical fullerenes. These tubes of carbon are usually only a few nanometres wide, but they can range from less than a micrometer to several millimeters in

length. They often have closed ends, but can be open-ended as well. There are also cases in which the tube reduces in diameter before closing off. Their unique molecular structure results in

extraordinary macroscopic properties, including high tensile strength, high electrical conductivity, high ductility, high heat conductivity, and relative chemical inactivity (as it is cylindrical

and "planar" — that is, it has no "exposed" atoms that can be easily displaced). One proposed use of carbon nanotubes is in paper

batteries, developed in 2007 by researchers at Rensselaer Polytechnic Institute.[24] Another highly speculative proposed use in the field of space technologies is to produce high-tensile carbon cables required

by a space elevator.

Main article: Carbon nanobud

Nanobuds have been obtained by adding fullerenes to carbon nanotubes.

The C60 fullerene in crystalline form

Main article: Aggregated diamond nanorod

Fullerites are the solid-state manifestation of fullerenes and related compounds and materials.

"Ultrahard fullerite" is a coined term frequently used to describe material produced by high-pressure high-temperature (HPHT) processing of fullerite. Such treatment converts fullerite into a

nanocrystalline form of diamond which has been reported to exhibit remarkable mechanical properties.[25]

For the past decade, the chemical and physical properties of fullerenes have been a hot topic in the field of research and development, and are likely to continue to be for a long time.

Popular Science has published articles about the possible uses of fullerenes in armor.[citation needed] In April 2003, fullerenes were under

study for potential medicinal use: binding specific antibiotics to the structure to

target resistant bacteria and even target certain cancer cells such as melanoma. The October 2005 issue of Chemistry & Biology contains an article describing the use of fullerenes as

light-activated antimicrobial agents.[26]

In the field of nanotechnology, heat resistance and superconductivity are some of the more heavily studied properties.

A common method used to produce fullerenes is to send a large current between two nearby graphite electrodes in an inert atmosphere. The resulting carbon plasma arc between the electrodes cools into sooty residue from which many fullerenes can be isolated.

There are many calculations that have been done using ab-initio quantum methods applied to fullerenes. By DFT and TD-DFT methods one can obtain IR, Raman and UV spectra. Results of such calculations can be

compared with experimental results.

Researchers have been able to increase the reactivity of fullerenes by attaching active groups to their surfaces. Buckminsterfullerene does not exhibit "superaromaticity": that is, the electrons in the hexagonal rings do not delocalize

over the whole molecule.

A spherical fullerene of n carbon atoms has n pi-bonding electrons, free to delocalize. These should try to delocalize over

the whole molecule. The quantum mechanics of such an arrangement should be like one shell only of the well-known quantum mechanical structure of a single atom, with a stable filled shell for

n = 2, 8, 18, 32, 50, 72, 98, 128, etc.; i.e. twice a perfect square number; but this series does not include 60. This

2(N + 1)2 rule (with N integer) for spherical aromaticity is the three-dimensional analogue of Hückel’s

rule. The 10+ cation would satisfy this rule, and should be aromatic. This has been shown to be the case using quantum chemical modelling, which showed the existence of strong diamagnetic sphere currents in the cation.

As a result, C60 in water tends to pick up two more electrons and become an anion. The nC60 described below may be

the result of C60 trying to form a loose metallic bond.

Main article: Fullerene chemistry

Fullerenes are stable, but not totally unreactive. The sp2-hybridized carbon atoms, which are at their energy minimum in planar graphite, must be bent to form the closed sphere or

tube, which produces angle strain. The characteristic reaction of fullerenes is electrophilic addition at 6,6-double bonds, which reduces angle strain by changing sp2-hybridized carbons into

sp3-hybridized ones. The change in hybridized orbitals causes the bond angles to decrease from about 120° in the

sp2 orbitals to about 109.5° in the sp3 orbitals. This decrease in bond angles allows for the bonds to bend less when closing the sphere or tube, and thus, the molecule

becomes more stable.

Other atoms can be trapped inside fullerenes to form inclusion compounds known as endohedral fullerenes. An unusual example is the egg shaped fullerene Tb3N@C84, which violates the isolated pentagon

rule.[28] Recent evidence for a meteor impact at the end of the Permian period was found by analyzing noble gases so preserved.[29] Metallofullerene-based inoculates using the rhonditic steel process are beginning production as one of the first commercially-viable uses of buckyballs.

C60 in solution

Fullerenes are sparingly soluble in many solvents. Common solvents for the fullerenes include aromatics, such as toluene, and others like carbon disulfide. Solutions of pure buckminsterfullerene have a

deep purple color. Solutions of C70 are a reddish brown. The higher fullerenes C76 to C84 have a variety of colors. C76 has two optical forms, while

other higher fullerenes have several structural isomers. Fullerenes are the only known allotrope of carbon that can be dissolved in common

solvents at room temperature.

Solvent

Solubility

1-chloronaphthalene

51 mg/mL

1-methylnaphthalene

33 mg/mL

1,2-dichlorobenzene

24 mg/mL

1,2,4-trimethylbenzene

18 mg/mL

tetrahydronaphthalene

16 mg/mL

carbon disulfide

8 mg/mL

1,2,3-tribromopropane

8 mg/mL

xylene

5 mg/mL

bromoform

5 mg/mL

cumene

4 mg/mL

toluene

3 mg/mL

benzene

1.5 mg/mL

cyclohexane

1.2 mg/mL

carbon tetrachloride

0.4 mg/mL

chloroform

0.25 mg/mL

n-hexane

0.046 mg/mL

tetrahydrofuran

0.006 mg/mL

acetonitrile

0.004 mg/mL

methanol

0.000 04 mg/mL

water

1.3×10−11 mg/mL

Some fullerene structures are not soluble because they have a small band gap between the ground and excited states. These include the small fullerenes C28,[30] C36 and C50. The C72 structure is also in this class, but the endohedral version with a

trapped lanthanide-group atom is soluble due to the interaction of the metal atom and the electronic states of the fullerene. Researchers had

originally been puzzled by C72 being absent in fullerene plasma-generated soot extract, but found in endohedral samples. Small band gap fullerenes are highly reactive and bind to other

fullerenes or to soot particles.

Solvents that are able to dissolve buckminsterfullerene (C60) are listed at left in order from highest solubility. The solubility value given is the approximate saturated

concentration.[31][32]

Solubility of C60 in some solvents shows unusual behaviour due to existence of solvate phases (analogues of crystallohydrates). For example, solubility of C60 in benzene solution shows maximum at about 313 K. Crystallization from benzene solution at temperatures below maximum results in formation of triclinic

solid solvate with four benzene molecules C60·4C6H6 which is rather unstable in air. Out of solution, this structure decomposes into usual fcc C60 in

few minutes’ time. At temperatures above solubility maximum the solvate is not stable even when immersed in saturated solution and melts with formation of fcc C60. Crystallization at

temperatures above the solubility maximum results in formation of pure fcc C60. Millimeter-sized crystals of C60 and C70 can be grown from solution both for

solvates and for pure fullerenes.[33][34]

Hydrated fullerene C60HyFn is a stable, highly hydrophilic, supra-molecular complex consisting of С60 fullerene molecule enclosed into the first hydrated shell that contains

24 water molecules: C60@(H2O)24. This hydrated shell is formed as a result of donor-acceptor

interaction between lone-electron pairs of oxygen, water molecules and electron-acceptor centers on the fullerene surface. Meanwhile, the

water molecules which are oriented close to the fullerene surface are interconnected by a three-dimensional network of hydrogen bonds. The size of C60HyFn is 1.6–1.8 nm. The maximal

concentration of С60 in the form of C60HyFn achieved by 2010 is 4 mg/mL.[35] [36][37][38]

In 1999, researchers from the University of Vienna demonstrated that wave-particle duality applied to molecules such as fullerene.[39] One of the co-authors of this research, Julian Voss-Andreae,

has since created several sculptures symbolizing wave-particle duality in fullerenes (see Fullerenes in popular

culture for more detail).

Science writer Marcus Chown stated on the CBC radio show Quirks and Quarks in May 2006 that scientists are trying to make

buckyballs exhibit the quantum behavior of existing in two places at once (quantum superposition).[40]

[

edit] Safety and toxicity

Moussa et al. (1996-7)[41][42]

studied the in vivo toxicity of C60 after intra-peritoneal administration of large doses. No evidence of toxicity was found and the mice tolerated a dose of 5 000 mg/kg of

body weight (BW). Mori et al. (2006) [43] could not find toxicity in rodents for C60 and

C70 mixtures after oral administration of a dose of 2 000 mg/kg BW and did not observe evidence of genotoxic or mutagenic potential in vitro. Other studies could not establish

the toxicity of fullerenes: on the contrary, the work of Gharbi et al. (2005)[44] suggested that aqueous

C60 suspensions failing to produce acute or subacute toxicity in rodents could also protect their livers in a dose-dependent manner against free-radical damage.

A comprehensive and recent review on fullerene toxicity is given by Kolosnjaj et al. (2007a,b, c).[45][46] These authors review the works on fullerene

toxicity beginning in the early 1990s to present, and conclude that very little evidence gathered since the discovery of fullerenes indicate that C60 is toxic.

With reference to nanotubes, a recent study by Poland et al. (2008)[47] on carbon nanotubes introduced into

the abdominal cavity of mice led the authors to suggest comparisons to "asbestos-like pathogenicity". It should be noted that this was not an

inhalation study, though there have been several performed in the past, therefore it is premature to conclude that nanotubes should be considered to have a toxicological profile similar to

asbestos. Conversely, and perhaps illustrative of how the various classes of molecules which fall under the general term fullerene cover a wide range of properties, Sayes et al. found

that in vivo inhalation of C60(OH)24 and nano-C60 in rats gave no effect, whereas in comparison quartz particles produced an inflammatory response under

the same conditions.[48] As stated above, nanotubes are quite different in chemical and physical properties to

C60, i.e., molecular weight, shape, size, physical properties (such as solubility) all are very different, so from a toxicological standpoint, different results for C60 and

nanotubes are not suggestive of any discrepancy in the findings.

When considering toxicological data, care must be taken to distinguish as necessary between what are normally referred to as fullerenes: (C60, C70, …); fullerene

derivatives: C60 or other fullerenes with covalently bonded chemical groups; fullerene complexes (e.g., water-solubilized with surfactants, such as C60-PVP; host-guest

complexes, such as with cyclodextrin), where the fullerene is physically bound to another molecule; C60 nanoparticles, which are extended solid-phase aggregates of C60

crystallites; and nanotubes, which are generally much larger (in terms of molecular weight and size) molecules, and are different in shape to the spheroidal fullerenes C60 and

C70, as well as having different chemical and physical properties.

The above different molecules span the range from insoluble materials in either hydrophilic or lipophilic media, to hydrophilic, lipophilic, or even amphiphilic molecules, and with other varying

physical and chemical properties. Therefore any broad generalization extrapolating for example results from C60 to nanotubes or vice versa is not possible, though technically all are

fullerenes, as the term is defined as a close-caged all-carbon molecule. Any extrapolation of results from one molecule to other molecules must take into account considerations based on a

quantitative structural analysis relationship study (QSARS), which mostly depends on how close the molecules under consideration are in physical and chemical properties.

After the synthesis of macroscopic amounts of fullerenes,[49] their physical properties could be investigated. Very

soon Haddon et al.[50] found that intercalation of alkali-metal atoms in solid C60 leads to

metallic behavior.[51] In 1991, it was revealed that potassium-doped C60 becomes

superconducting at 18 K.[52] This was the highest

transition temperature for a molecular superconductor. Since then, superconductivity has been reported in fullerene doped with various other alkali metals.[53][54] It has been shown that the superconducting

transition temperature in alkaline-metal-doped fullerene increases with the unit-cell volume V.[55][56] As caesium forms the largest alkali ion, caesium-doped fullerene is an

important material in this family. Recently, superconductivity at 38 K has been reported in bulk Cs3C60,[57] but only under applied pressure. The highest superconducting transition temperature of 33 K at

ambient pressure is reported for Cs2RbC60.[58]

The increase of transition temperature with the unit-cell volume had been believed to be evidence for the BCS mechanism of C60

solid superconductivity, because inter C60 separation can be related to an increase in the density of states on the Fermi level, N(εF). Therefore, there have been many

efforts to increase the interfullerene separation, in particular, intercalating neutral molecules into the A3C60 lattice to increase the interfullerene spacing while the

valence of C60 is kept unchanged. However, this ammoniation technique has revealed a new aspect of fullerene intercalation compounds: the Mott-Hubbard transition and the correlation

between the orientation/orbital order of C60 molecules and the magnetic structure.[59]

The C60 molecules compose a solid of weakly bound molecules. The fullerites are therefore molecular solids, in which the molecular properties still survive. The discrete levels of a

free C60 molecule are only weakly broadened in the solid, which leads to a set of essentially nonoverlapping bands with a narrow width of about 0.5 eV.[51] For an undoped C60 solid, the 5-fold hu band is the HOMO level, and the 3-fold t1u band is the empty LUMO level, and this system is a band

insulator. But when the C60 solid is doped with metal atoms, the metal atoms give electrons to the t1u band or the upper 3-fold t1g band.[60] This partial electron occupation of the band leads to sometimes metallic behavior. However, A4C60 is an

insulator, although the t1u band is only partially filled and it should be a metal according to band theory.[61] This unpredicted behavior may be explained by the Jahn-Teller

effect, where spontaneous deformations of high-symmetry molecules induce the splitting of degenerate levels to gain the electronic energy. The Jahn-Teller type electron-phonon interaction is

strong enough in C60 solids to destroy the band picture for particular valence states.[59]

A narrow band or strongly correlated electronic system and degenerated ground states are important points to understand in explaining superconductivity in fullerene solids. When the

inter-electron repulsion U is greater than the bandwidth, an insulating localized electron ground state is produced in the simple Mott-Hubbard model. This explains the absence of

superconductivity at ambient pressure in caesium-doped C60 solids.[57]

Electron-correlation-driven localization of the t1u electrons exceeds the critical value, leading to the Mott insulator. The application of high pressure decreases the interfullerene

spacing, therefore caesium-doped C60 solids turn to metallic and superconducting.

A fully developed theory of C60 solids superconductivity is still lacking, but it has been widely accepted that strong electronic correlations and the Jahn-Teller electron-phonon

coupling[62] produce local electron-pairings that show a high transition temperature close to the insulator-metal

transition.[63]

Some fullerenes (e.g. C76, C78, C80, and C84) are inherently chiral because they are

D2-symmetric, and have been successfully resolved. Research efforts are ongoing to develop specific sensors for their enantiomers.

Main article: Fullerenes in popular culture

Examples of fullerenes in popular culture are numerous. Fullerenes appeared in fiction well before scientists took serious interest in

them. In New Scientist there used to be a weekly column called "Daedalus" written by David Jones, which contained humorous descriptions of

unlikely technologies. In 1966 [64] Jones suggested that it may be possible to create giant hollow carbon molecules by

distorting a plane hexagonal net by the addition of impurity atoms.

On 4 September 2010, Google used an interactively rotatable fullerene C60 as the second ‘o’ in their logo to celebrate the 25th anniversary of the discovery of the fullerenes.[65][66]

歡迎來到Bewise Inc.的世界,首先恭喜您來到這接受新的資訊讓產業更有競爭力, 我們是提供專業刀具製造商,應對客戶高品質的刀具需求,我們可以協助客戶滿足您對產業的不同要求,我們有能力達到非常卓越的客戶需求品質,這是現有相關技

術無法比擬的,我們成功的滿足了各行各業的要求,包括:精密HSS DIN切削刀具、協助客戶設計刀具流程、DIN or JIS 鎢鋼切削刀具設計、NAS986 NAS965 NAS897 NAS937orNAS907 航太切削刀具,NAS航太刀具設計、超高硬度的切削刀具、醫療配件刀具設計、複合式再研磨機、PCD地板專用企口鑽石組合刀 具、粉末造粒成型機、主機版專用頂級電桿、PCD V-Cut刀、捨棄式圓鋸片組、粉末成型機、航空機械鉸刀、主機版專用頂級電感、’汽車業刀具設計、電子產業鑽石刀具、木工產業鑽石刀具、銑刀與切斷複合再研磨機、銑刀與鑽頭複合再研磨機、銑刀與螺絲攻複合再研磨機等等。我們的產品涵蓋了從民生 刀具到工業級的刀具設計;從微細刀具到大型刀具;從小型生產到大型量產;全自動整合;我們的技術可提供您連續生產的效能,我們整體的服務及卓越的技術,恭 迎您親自體驗!!

BW Bewise Inc. Willy Chen willy@tool-tool.com bw@tool-tool.com www.tool-tool.com skype:willy_chen_bw mobile:0937-618-190 Head &Administration Office

No.13,Shiang Shang 2nd St., West Chiu Taichung,Taiwan 40356 http://www.tool-tool.com / FAX:+886 4 2471 4839 N.Branch

5F,No.460,Fu Shin North Rd.,Taipei,Taiwan S.Branch No.24,Sec.1,Chia Pu East Rd.,Taipao City,Chiayi Hsien,Taiwan

Welcome to BW tool world! We are an experienced tool maker specialized in cutting tools. We focus on what you

need and endeavor to research the best cutter to satisfy users’ demand. Our customers involve wide range of industries, like mold & die, aerospace,

electronic, machinery, etc. We are professional expert in cutting field. We would like to solve every problem from you. Please feel free to contact us, its our pleasure to serve for you.

BW product including: cutting tool、aerospace tool

.HSS DIN Cutting tool、Carbide end

mills、Carbide cutting tool、NAS Cutting

tool、NAS986 NAS965 NAS897 NAS937orNAS907 Cutting Tools,Carbide

end mill、disc milling cutter,Aerospace cutting tool、hss drill’Фрезеры’Carbide drill、High speed steel、Compound Sharpener’Milling cutter、INDUCTORS FOR PCD’CVDD(Chemical Vapor Deposition Diamond )’PCBN (Polycrystalline Cubic Boron Nitride) ’Core

drill、Tapered end mills、CVD Diamond Tools Inserts’PCD Edge-Beveling Cutter(Golden Finger’PCD

V-Cutter’PCD Wood tools’PCD Cutting

tools’PCD Circular Saw Blade’PVDD End

Mills’diamond tool. INDUCTORS FOR PCD

. POWDER FORMING MACHINE ‘Single Crystal Diamond

‘Metric end mills、Miniature end

mills、Специальные режущие инструменты ‘Пустотелое сверло ‘Pilot

reamer、Fraises’Fresas con mango’ PCD (Polycrystalline diamond) ‘Frese’POWDER FORMING

MACHINE’Electronics cutter、Step

drill、Metal cutting saw、Double margin

drill、Gun barrel、Angle milling

cutter、Carbide burrs、Carbide tipped

cutter、Chamfering tool、IC card engraving

cutter、Side cutter、Staple

Cutter’PCD diamond cutter specialized in grooving floors’V-Cut PCD Circular

Diamond Tipped Saw Blade with Indexable Insert’ PCD Diamond Tool’ Saw Blade with

Indexable Insert’NAS tool、DIN

or JIS tool、Special

tool、Metal slitting saws、Shell end

mills、Side and face milling cutters、Side chip

clearance saws、Long end mills’end mill

grinder’drill grinder’sharpener、Stub roughing end mills、Dovetail milling cutters、Carbide slot drills、Carbide torus cutters、Angel carbide end mills、Carbide torus cutters、Carbide ball-nosed slot

drills、Mould cutter、Tool manufacturer.

Bewise Inc. www.tool-tool.com

ようこそBewise Inc.の 世界へお越し下さいませ、先ず御目出度たいのは新たな

情報を受け取って頂き、もっと各産業に競争力プラス展開。

弊社は専門なエンド・ミルの製造メーカーで、客先に色んな分野のニーズ、

豊富なパリエーションを満足させ、特にハイテク品質要求にサポート致します。

弊社は各領域に供給できる内容は:

(1)精密HSSエンド・ミ ルのR&D

(2)Carbide Cutting tools設計

(3)鎢鋼エンド・ミ ル設計

(4)航空エンド・ミ ル設計

(5)超高硬度エンド・ミ ル

(6)ダイヤモンド・エ ンド・ミル

(7)医療用品エンド・ミ ル設計

(8)自動車部品&材料加工向けエンド・ミ ル設計

弊社の製品の供給調達機能は:

(1)生活産業~ハイテク工業までのエン ド・ミル設計

(2)ミクロ・エ

ンド・ミル~大型エンド・ミル供給

(3)小Lot生産~大量発注対応供給

(4)オートメーション整備調達

(5)スポット対応~流れ生産対応

弊社の全般供給体制及び技術自慢の総合専門製造メーカーに貴方のご体験を御待ちしております。

Bewise Inc. talaşlı imalat sanayinde en fazla kullanılan ve üç eksende (x,y,z) talaş kaldırabilen freze takımlarından olan Parmak Freze imalatçısıdır. Çok geniş ürün yelpazesine sahip

olan firmanın başlıca ürünlerini Karbür Parmak Frezeler, Kalıpçı Frezeleri, Kaba Talaş Frezeleri, Konik Alın Frezeler, Köşe Radyüs Frezeler, İki Ağızlı Kısa ve Uzun Küresel Frezeler, İç Bükey

Frezeler vb. şeklinde sıralayabiliriz.

BW специализируется в научных исследованиях и разработках, и снабжаем самым высокотехнологичным карбидовым материалом для поставки

режущих / фрезеровочных инструментов для почвы, воздушного пространства и электронной индустрии. В нашу основную продукцию входит твердый карбид / быстрорежущая сталь, а также двигатели,

микроэлектрические дрели, IC картонорезальные машины, фрезы для гравирования, режущие пилы, фрезеры-расширители, фрезеры-расширители с резцом, дрели, резаки форм для шлицевого вала / звездочки

роликовой цепи, и специальные нано инструменты. Пожалуйста, посетите сайт www.tool-tool.com для получения

большей информации.

BW is specialized in R&D and sourcing the most advanced carbide material with high-tech coating to supply cutting / milling

tool for mould & die, aero space and electronic industry. Our main products include solid carbide / HSS end mills, micro electronic drill, IC card cutter, engraving cutter, shell end mills,

cutting saw, reamer, thread reamer, leading drill, involute gear cutter for spur wheel, rack and worm milling cutter, thread milling cutter, form cutters for spline shaft/roller chain sprocket,

and special tool, with nano grade. Please visit our web www.tool-tool.com for more info.